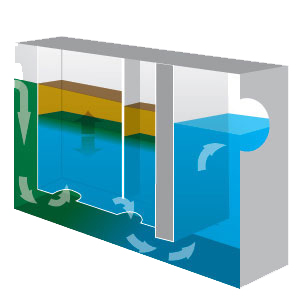

The application for authorization to construct shall be signed by the owner proprietor or responsible official and include. Grease traps usually consist of an underground watertight concrete tank with baffled inlet and outlet piping.

Appendix A Grease Interceptor And Grease Trap Sizing

Remove any baffles and scrape clean.

. Calculate the capacity of the fixture ex. Hydromechanical Grease Interceptors HGI Hydromechanical grease interceptors shall meet the following requirements. Water temperatures must be less than 120 degrees prior to entering grease trap.

More importantly these codes may require a plumber MEP engineer to estimate the size of the trap by 2 options. Local plumbing codes can also be used to determine the installation and design criteria for commercial grease traps. After cleaning the baffles can be rinsed off in the sink that flows to the trap.

Capacity of the sink your grease trap is servicing by measuring the. From sinks and dishwashers to allow for adequate cooling of the wastewater. Clean the bypass vent with a flexible probe or wire.

Must be constructed of non-corrodible materials. Single below-ground grease interceptors and those installed in series must be directly accessible from the surface. Grease trap flow rating Total fixture unit count x 3 gallonsminute The minimum liquid holding capacity of the trap is calculated by multiplying the grease trap flow rating in gallons per minutes times twelve minutes.

Using a strainer scrape the bottom of the trap to remove all non-floatable food particles and debris. It is as much a manufacturers standard as it is a guide for specifiers. If commercial dishwashers are discharged through a grease interceptor care must be taken in system design.

Contact information for the owner proprietor or responsible official o b. Grease Interceptor Design Criteria Technical Specifications A. OSHA Walking Working Standards for Grease Trap Hazard Prevention Employers must protect workers from tripping or stepping into or through any hole that is less than 4 feet above a lower level by using covers or a guardrail system.

Grease Interceptor Sizing Calculator Grease Trap Sizing Calculator Guide One AHJ web site. Convert A to gallons. Huge Selection of Plumbing Supplies In Stock.

Grease trapsinterceptors shall be located to be easily accessible for cleaning. Water temperatures must be less than 120 degrees prior to entering grease trap. Grease Traps specifies a nominal size NS a repeatable sizing method provides performance based criteria for product design and quality control.

Ladle off the layer of grease and oil floating on top of the water. The minimum access opening dimensions shall be 18 inches x 18 inches or a minimum of 24 inches in diameter. Free Shipping Over 99.

Must be flow-rated at 75-gallons per minute GPM or higher. A grease trapinterceptor is designed to slow wastewater discharged from fixtures in order to allow enough time for FOG and solid waste to separate from the waste water. The grease interceptor must provide sufficient retention time for emulsified FOG to separate and float to the surface of the chamber.

The resulting figure is now in gallons. 302 Grease traps shall be installed at a minimum distance of 10 ft. Incorporated into grease trap design.

The outlet pipe has a tee that allows the internal discharge to be located within 03. Grease trap liquid holding capacity gallons grease trap flow rating x 12 minutes. Local plumbing codes typically determine design and installation criteria but they typically follow the guidelines set forth by the Plumbing Drainage Institute PDI.

An appropriately sized under-the-counter grease trap with County approval. When it is 25 full of grease it should be emptied. The grease trapgrease interceptor shall be constructed with a minimum of two baffles.

The guideline in the standard states that grease traps should be emptied at least once a month or preferably twice a month. Shall be approved by the Community Compliance Supervisor or designee. Must comply with American Society of Civil Engineers ASME A112143 standard.

Grease traps are to be installed at a minimum distance of 10 ft. Food solids entering the grease trapinterceptor should. Grease traps are to be installed at a minimum distance of 10 ft.

Grease Interceptor Design criteria Customers who are required to pass water through a grease trap or other interceptor will provide a minimum 12 minute retention time at theoretical peak flow rate between the influent and effluent baffles. A grease trap under European design criteria is typically a large tank that goes into basements or into the ground outside. The standard grease interceptor shall be constructed with a minimum of two baffles.

1 gallon is equal to 231 cubic inches. All grease bearing waste streams should be. For sites that discharge to the Orange County wastewater system grease interceptor design and sizing is regulated by both the Florida Plumbing Code Chapter 10 Section 1003 and the Orange.

Essentially a grease trap works by using gravity to separate heavier water from lighter fats. From sinks and dishwashers to allow for adequate cooling of the wastewater. The two ends of the design spectrum are linked.

The grease interceptor must provide. 29 CFR 191028b3ii Employers must protect workers from falling through any hole that is 4 feet or more above. Grease interceptors are to be installed at a distance of 8-10 meters from the last contributing fixture to allow for adequate cooling of the wastewater while preventing grease solidification in the lines.

Ad Call Now To Speak With Our Dedicated Customer and Product Support Teams. Twenty-five Percent Rule - Standard for the determination of grease trap or interceptor maintenance requirements to ensure that minimum design requirements for FOG removal are met such that the combined FOG and solids accumulation in the tank does not exceed 25 of the operating depth design hydraulic depth of the tank. Basic Design Criteria Grease interceptors must be designed to satisfy four basic criteria in order to ensure effective separation.

The International Standard EN 1825. Grease Interceptor Design Guidelines 54-7.

Micro Sewage Solutions Tinos Eco Lodge Grey Water System Diy Grey Water System Water Filter Diy

Cross Section Of Typical Grease Interceptor Download Scientific Diagram

Sec 5 1 67 4 Grease Interceptor Standards Of Construction

Grease Interceptor Sizing Guide Webstaurantstore

Bangalore Treating Kitchen Waste Water For Reuse Kitchen Waste Grey Water System Water Treatment

0 comments

Post a Comment